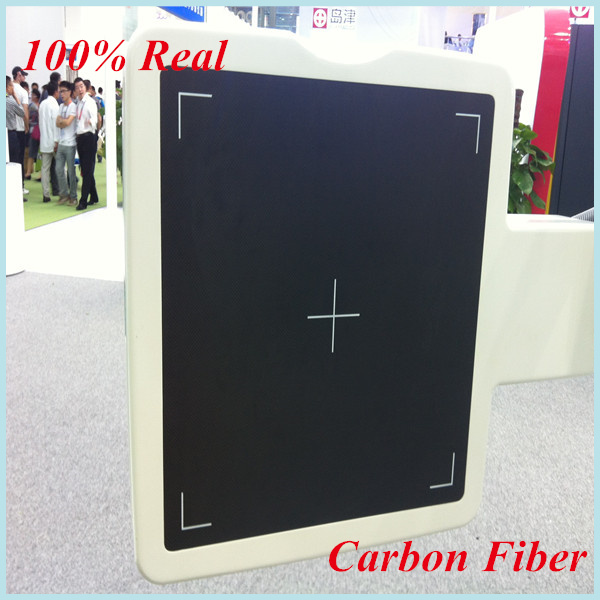

The traditional radioactive medical panels must increase the voltage for the purpose of diagnosis and treatment, but the increased radiation energy of the radiation can have harmful side effects to the patient. As a new type of material, carbon fiber has become an excellent material for making medical boards.

The most common application of carbon fiber is on medical CT bed plates, because carbon fiber has good X-ray transmission capability, and its X-ray transmittance is over 96%. Aluminum equivalent is a measure of the permeability of a material x ray. The smaller the aluminum equivalent, the better the X-ray transmission performance. The carbon fiber medical board has a small aluminum equivalent, so its X-ray transmission performance is better than that of a conventional medical sheet such as a plywood or a phenol resin board, and the carbon fiber allows X-rays to be irradiated on the board at any degree without refraction.

The mechanical properties required for certain components on medical equipment vary by direction. Take the medical board as an example. The vertical direction is the main bearing capacity and the horizontal direction is the vehicle assistance. Carbon fiber materials have anisotropic characteristics, and their performance along the fiber axis direction and the vertical fiber axis direction are significantly different. Based on this feature, we can reasonably design the construction of the device.

In addition, the specific strength and specific stiffness of carbon fiber materials are higher than many other knot materials, and its corrosion resistance is also very strong. In the case of alcohol, acidic liquids, drugs, etc., deformation does not occur. For expensive medical equipment, the durability of carbon fiber can save a lot of cost.

Post time: Nov-15-2019