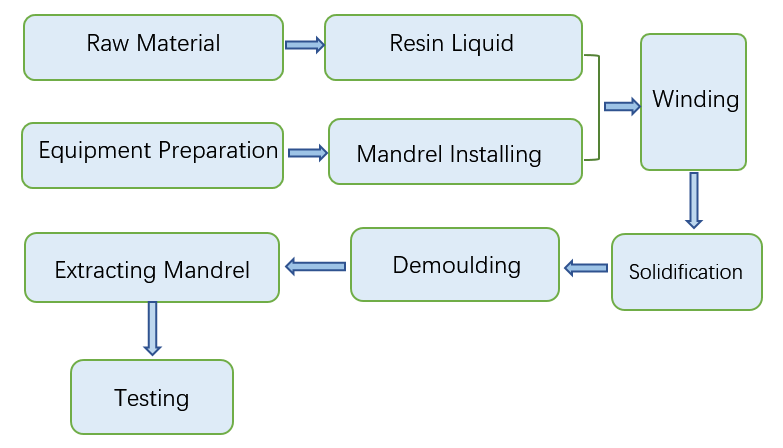

Winding process is a method of making carbon fiber tubes.According to the physical and chemical state of resin matrix in filament winding, it is divided into three processes: dry winding, wet winding and semi dry winding,as shown in the following schematic:

1.Dry winding

can strictly control the resin content (accurate to less than 2%), which owns high production efficiency(the winding speed is up to 100~200m/min).

2.Wet Winding

There are series of advantages for Wet Winding:

- Cost less 40% than dry winding ;

- Good air tightness and low bubble;

- Carbon fibers is arranged regularly,

- Reducing the wear of carbon fiber;

- High production efficiency (up to 200m/min)

3.Semi-dry method of winding

Compared with the dry method, the prepreg process and equipment are eliminated, and the bubble content in the products can be reduced compared with the wet method.

Post time: Sep-15-2017