Carbon fiber, composed of combos of not like materials (fiber and resin), their variability, and so, tailorability, square measure central to their charm. As a metal replacement, carbon fiber composites provide ten times the strength of steel. Carbon fiber producers create product that square measure similar however not identical. Carbon fiber varies in tensile modulus (or stiffness determined as deformation below strain) and tensile, compression and fatigue strength

PAN-based carbon fiber is obtainable these days in low modulus (less than thirty-two million lbf/in² or Msi), customary modulus (33 to thirty-six Msi), intermediate modulus (40 to fifty Msi), high modulus (50 to seventy Msi) and ultrahigh modulus (70 to one hundred forty Msi).

In simplest terms, carbon fiber is created by shift of associate degree organic precursor fiber in associate degree inert atmosphere at temperatures higher than 1800°F (982.22 °C). Carbon fiber manufacture, however, may be an advanced enterprise.

Polymerization And Spinning

Polymerization

The process begins with a chemical compound feed stock referred to as a precursor that has the molecular backbone of the fiber. Today, regarding 100 percent of the carbon fiber created is created of cloth or pitch-based precursors, however most of it comes from polyacrylonitrile (PAN), manufactured from nitrite, and nitrite comes from the industrial chemicals propane and ammonia.

Oxidation And Carbonization

Oxidation

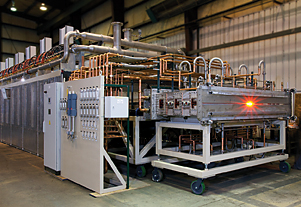

These bobbins square measure loaded into the basket, and within longest production, oxidization stage, PAN fibers square measure fed through a series of dedicated furnaces. Before they enter the primary kitchen appliance, the PAN fibers square measure placate into a tow or sheet referred to as a warp. The chamber temperature ranges from 392 °F (ca. 200 °C) to 572 °F (300 degree Celsius).

Surface treatment and sizing

Surface treatment and sizing

The next step is essential to fiber performance, and additionally to the precursors, it best distinguishes one supplier's product from competitors' product. The adhesion between the matrix organic compound and therefore the carbon fibers are essential for reinforcing the composite; throughout the carbon fiber producing method, a surface treatment is performed to boost this adhesion.

Post time: Nov-01-2018