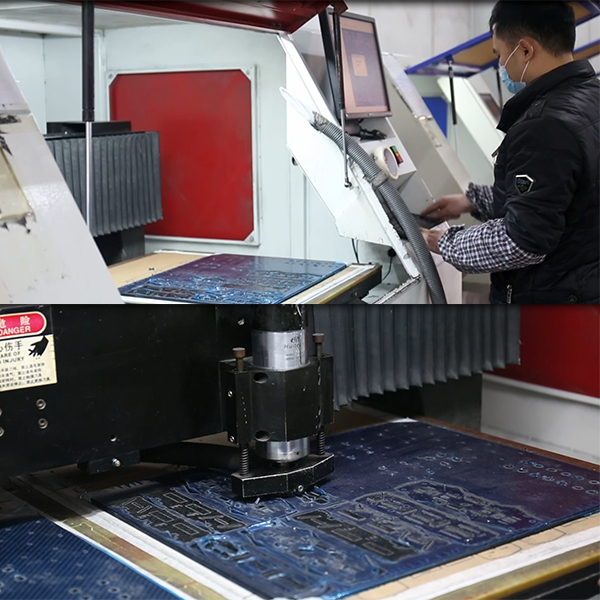

CNC machining is precision and cost-effective way to achieve innovation and creativity, which triggers out our endless imagination and creative inspiration. We had made so many different carbon fiber CNC parts for racing parts, RC helicopters, bicycle bracket, and reinforcements for 10 years. Usually, these structural components include a wide range of processes such as printing logo, cutting edges, cutout, drilling holes on the solid sheet or tubes. All the machining parts are controlled by our CNC technicians, and both tolerance and surface quality are strictly inspected by the quality inspection department before shipping the goods. Integrated CNC machining enables us to help our customers produce parts efficiently. Just send us AutoCAD files in form of DFX, DWG or solid works files if any demand.

| Name | Carbon Fiber CNC Parts | Material | 100% Carbon Fiber |

| Shape | Custom | Weave | 2x2 Twill, Plain |

| Size | Custom | Pattern | 1k, 3k, 6k |

| Thickness | 0.2-60 mm | Surface | Matte, Semi glossy, High glossy |

| Color | Black, Silk, Red, Blue, Green, Gold | ||

| Advantage | High strength, Lightweight, Corrosion resistance, High-pressure resistance, etc | ||

| Tolerance | Depends on the thickness of the parts | ||

| Machining type | Countersink, Slot cut, T-countersink, Drilling hole, Engrave, Fillet radius, Edge chamfering, Logo(silk screen printing, Laser engraving),3D parts. | ||

Found in 2008, XC Carbon Fiber is specialized in the production and sales of carbon fiber plate, carbon fiber molding products, carbon fiber tubes, CNC aluminum alloy high precision parts , carbon fiber CNC processing parts ,unmanned aircraft carbon fiber, aluminum alloy parts, carbon fiber-shaped products, carbon CNC processing , all kinds of hardware and electrical insulation processing parts. We had applied for two invention patents and 16 new technology patents and 4 The appearance of patents until 2018. We have already got 20 patents and received a patent certificate, while we applied for national high-tech enterprises. We obey "quality first, service-oriented, reasonable price," with high quality, efficient, fast service to establish long-term partnerships with every customer. Continuing to improve our products and services, go further with our clients and reach win-win between us and clients. Covering an area of about 2500m², our factory has good production capability, sale scale. The annual production of carbon fiber sheet increased to 60,000 pieces. The establishment of a new department and management system made us improving continuously, the number of employees is more than 200. All these can ensure us to offer the best service of quality assurance, timely delivery, and

1. What’s the feature of your product?

There are many good characteristics of our carbon fiber product, such as lightweight, high strength, durable, and fashion, etc.

2. Can I have a sample order?

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable. Some product we can offer free sample. Clients just need to bear the shipping cost.

3. What is the lead time?

Sample needs 1-3 days, mass production depends on order quantity. Normally 6-9 days.

4. Can you accept the mixed batch of different products?

Yes, we are support different product mix wholesale, no limit of raw materials and mechanical parts, and color specifications, etc.

5. What file need if need to do CNC Cutting or molding products?

We Need CAD DXF or DWG files for CNC cutting, 3D, STEP, STP, IGS File for molding.

6. How do we do quality control?

We have inspectors to check each procedure to avoid any mistake.

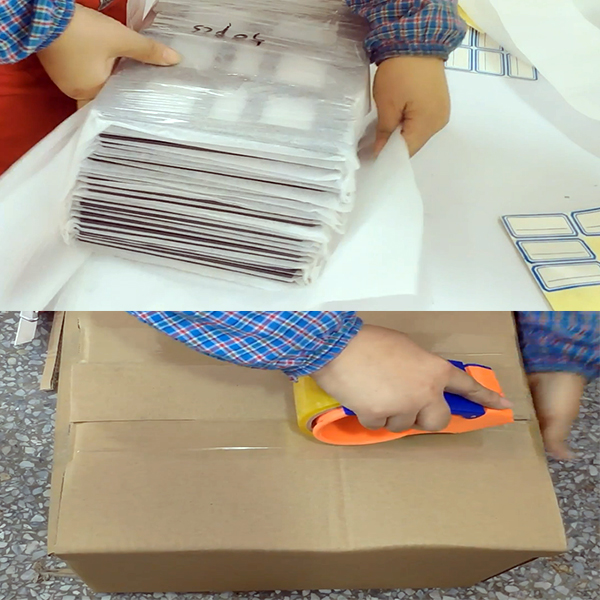

7. How do you pack the goods?

We wrap the goods with soft plastic bags first and then pack it using a cardboard box with foam board inside.

8. How is your after-sale service?

We provide our clients with excellent after-sale service including logistics tracking, application guide, problem solution, etc.

our customer's trust.

Only the user is the consumer of our products, so we have always emphasized the “user-centric product design concept.” Understand and analyze the real needs of users, through professional design means, methods to solve related problems, for users to create super-expected value, and achieve enterprise strategy.

Carbon fiber sample district, full carbon fiber plate,tubes,cnc parts,money clips,cigar case,FPV frame……you can find much carbon fiber product here. If interested just send us your carbon fiber design to achieve our first cooperation.We keep a stock of our samples every month and they are of good quality.The most classic sample color is black matte, and most people like this surface. But if you’re fond of colorful stuff, there are also much color plates & tubes with silk. All samples are from the engineer’s masterpiece, who make the carbon fiber alive. We almost send hundreds of free sample to our new partners every month, and get good reputation.We also believe these sample will be our first chance to make the business cooperation.

Founded in 2008, our company only produce carbon plates. Carbon fiber materials are not widely used at that time, so it’s hard to explore the market. And the outbreak of the 2008 financial crisis also took much opportunities and challenges.

Our production equipment was not so good, but we own great technique and technician. 3 years later, our production line was expanded from carbon fiber sheet to carbon fiber tube and CNC machining, the previously outdated device were replaced by advanced production equipment. Many professional staff continue to join us, the establishment of a new department and management system made us improving continuously , the number of employees is more than 100.

With the increasing popularity of carbon fiber, more and more people advocate and like the use of carbon fiber, many countries have high market demand.

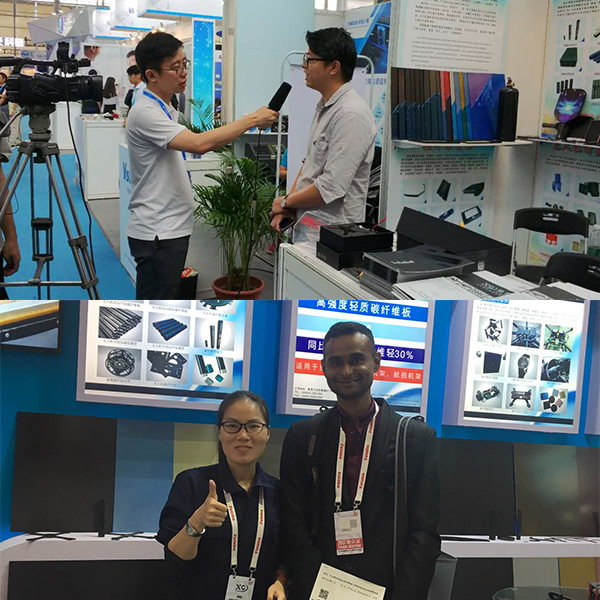

In the fierce competition environment in the industry, we rely on good quality and service to win market share and reputation, good product sales performance has brought sufficient original capital accumulation. Until 2017, we obtained a total of 20 patents and other national Advanced enterprise certificates. Many journalists began to visit the door, more and more partners, our business scope for the first time exceeded 80 countries. As a result, we have grown rapidly to be a well-known supplier.In 2013, QC department was set up, it’s responsible for the quality inspection of all products, to ensure our customers receive high-quality products. At the mean time, the establishment of the Molding department has also made our product line to be expanded again.

1.Keep innovation alive

The development of technology can always bring new possibilities to the innovation of design. With innovative technology, innovative design will always follow, will not stop in one place.

2.Emphasis on practicality

In addition to meeting functional standards, products must also meet psychological and aesthetic standards. Good design emphasizes the practicality of the product while abandoning any part that could be detrimental to the practicality of the product.

3.Caring about every detail

Don’t leave casual or unexpected places. Every care and precise expression in the design process demonstrates the designer’s respect for the user.

2018 HOBBY EXPO CHINA 2018 Shanghai Composites Model Exhibition